Model:

ET-FAR1SHM

Specifciation:

Size:L*W*H 4000*1570*2140mm

Applicable bottle diam:φ:20~320mm H:30~350mm

Applicable Label Size:L:20~350mm W:20~250mm

Power Supply:AC380V 50/60Hz

Max outer diameter of the label roll:500mm

Inner diam of the label roll:75mm

Labeling speed:80~300 PCS/min

Weight:2300KG

Power:13000W

Labeling accuracy:±1mm

Product introduction:

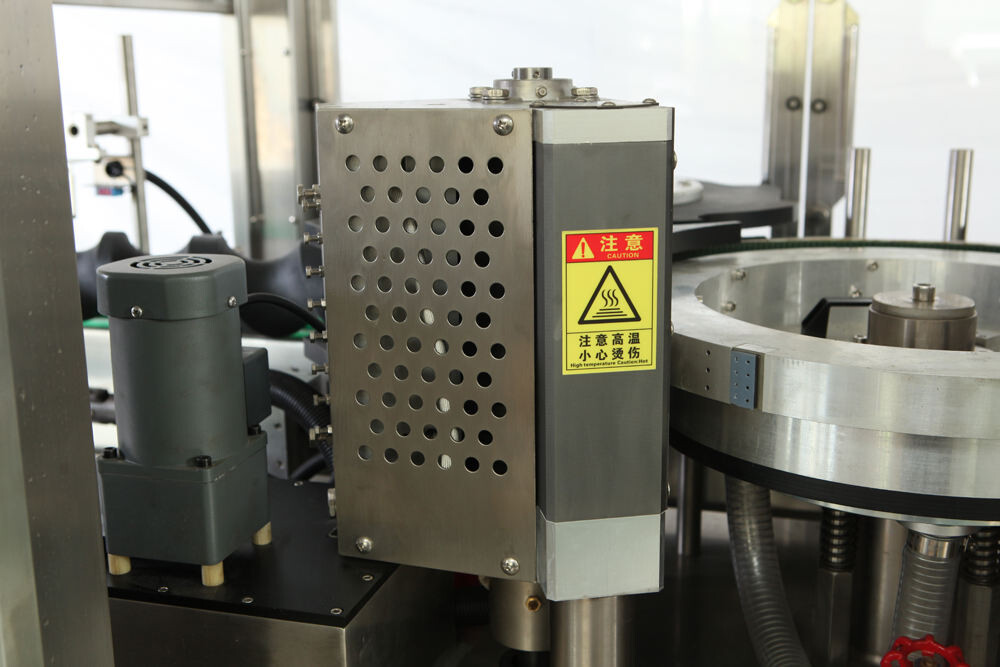

"Hot melt adhesive labeling machine is a commonly used equipment in the modern packaging industry, which uses heated and melted hot melt adhesive to stick the label onto the packaged object. Its working principle includes heating, melting, spraying, and label pasting of hot melt adhesive, which is completed by multiple parts working together. The hot melt adhesive labeling machine is suitable for OPP full week attachment of PET, PP, PE round and square bottles of mineral water, beverages, milk, dishwashing detergent, etc. The feeding materials are roll type OPP, paper, and paper plastic composite materials, suitable for accurate labeling at various speeds and high speeds; Centralized hot melt adhesive supply and return system, with low standard damage and adhesive consumption; The adhesive pattern is beautiful and suitable for transparent label paper. Fully automatic logic program control, human-machine interface, easy operation and maintenance. Compared with traditional labeling machines, rotary hot melt adhesive labeling machines have the following advantages:

1. Stronger adaptability: The rotary hot melt adhesive labeling machine is suitable for products of various shapes, while traditional labeling machines are only suitable for products of specific shapes.

2. Higher efficiency: The rotary hot melt adhesive labeling machine can complete a large amount of labeling work in a short period of time, while traditional labeling machines have slower speeds.

3. More precise bonding: The rotary hot melt adhesive labeling machine can achieve high-precision label bonding on products of different shapes, while traditional labeling machines have lower precision."