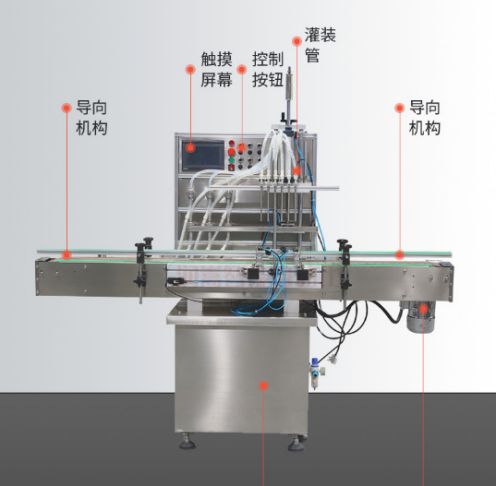

Product Details

Model:

CD-ARFCF1

CD-ARFCF2

CD-ARFCF4

CD-ARFCF6

Specifciation:

"Power supply: 220V 50/60Hz

Power: 2000W

Speed: 20-30bottle/min

Size(L*W*H): 200*130*160mm

Weight:400 kg"

Product introduction:

" Adopting a peristaltic pump filling method without valves or seals, it is the preferred choice for filling juice, medicine, pharmaceuticals, essential oils, disinfectant water, or corrosive materials. This equipment has good sealing performance and self-priming ability, which can prevent material backflow. It uses two peristaltic pumps to drive two filling heads, with high filling accuracy and easy operation. It has the functions of no filling due to missing bottles and automatic counting. The filling process can be automatically operated by setting the filling amount, number of filling heads, and capping time through the touch screen on the equipment, and the process is basically one click operation. Adopting high-precision enclosed cam indexing station, it has high precision, stable and reliable operation, and long service life. The human-machine interface setting and operation are intuitive and convenient, with PLC control and stable operation; Variable frequency control, adjustable production speed and automatic counting function; Automatic shutdown function, no bottle, no cap, no cap rotation; High precision cam indexing control, precise positioning. Made of SUS304 stainless steel, fully compliant with GMP requirements.

Product features:

1. Using well-known domestic and foreign brands of electrical and pneumatic components, with low failure rate, stable and reliable performance, and long service life;

2. Food grade silicone tubing is used in contact with materials, which is corrosion-resistant, easy to disassemble and clean, and meets food hygiene standards;

3. The filling volume and filling speed are easy to adjust, and there are no bottle or material stop filling options available;

4. The filling nozzle is submersible filling, which can effectively prevent the filling material from foaming or splashing out;

5. The filling nozzle has a suction function to ensure that there is no wire drawing or dripping during filling;"

Related Suggestion

Online Consultation

———

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.