Model:

ET-SAL2S

Specifciation:

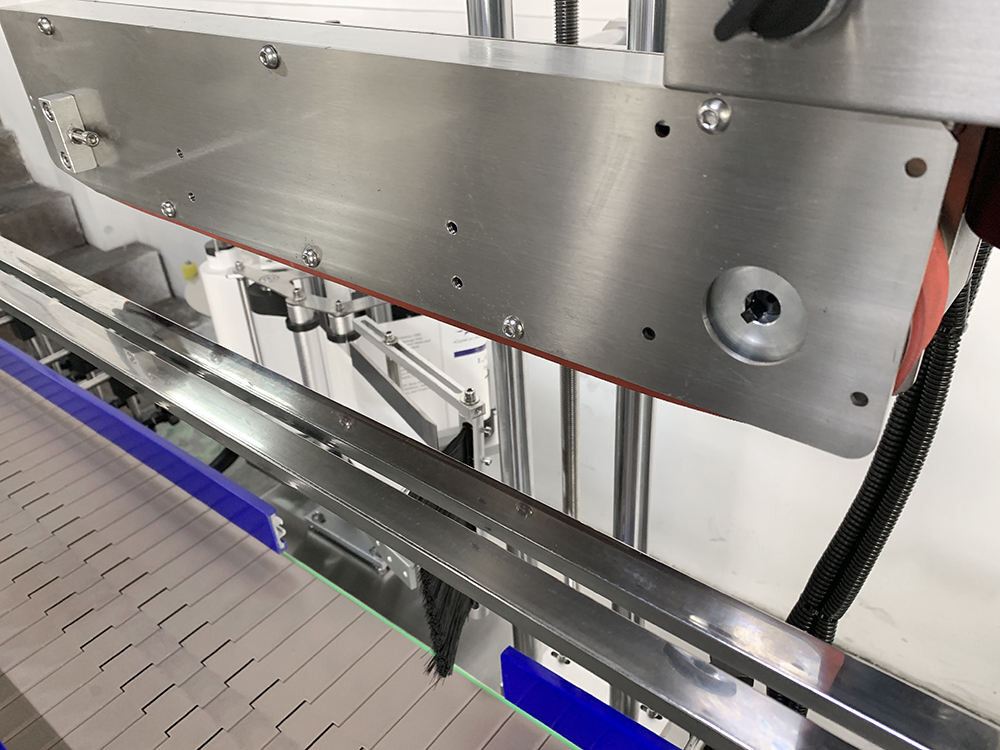

Size:L*W*H 1050*1000*1450mm

Applicable bottle diam:L:15~120mmW :30~150mm H:60~350mm

Applicable Label Size:L:15~250mm W:15~150mm

Power Supply:AC220V 50/60Hz

Max outer diameter of the label roll:280mm

Inner diam of the label roll:75mm

Labeling speed:15~35 PCS/min

Weight:155KG

:1000W

abeling accuracy:±1mm

Product introduction:

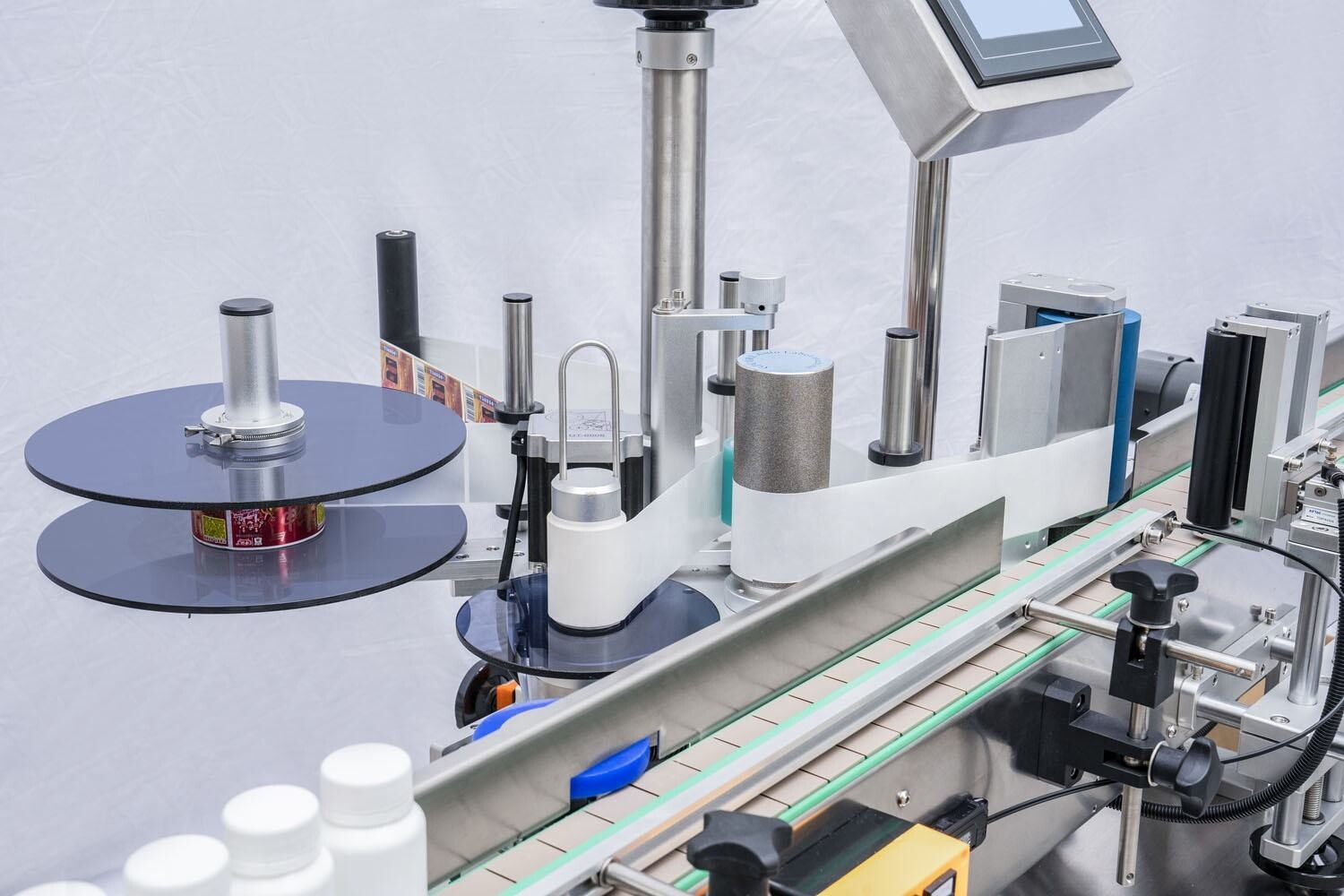

"The fully automatic single label machine is suitable for circular or square can bodies, paper tubes, etc. with a diameter of 30-300mm and a height of 40-600mm for full circumference labeling. It can also be used for full circumference or full body labeling. It is widely used in packaging industries such as food and beverage, pesticide and chemical, paint and coating, and healthcare. Purpose: To achieve automatic attachment of adhesive labels and films on the circumferential surface, conical surface, and four aspects of the product; One machine can achieve labeling of round bottles from 20mm to 200mm straight.

The labeling is smooth, wrinkle free, bubble free, with good labeling accuracy, high efficiency, and good stability;

The clever design of using mechanical adjustment of partially structured combinations and label winding, with 6 degrees of freedom for easy fine-tuning of the labeling position (which can be fixed after adjustment), makes the conversion adjustment and label winding between different products simple and time-saving;

Core working principle: After the bottle separation mechanism separates the products, the sensors detect the products passing through and transmit signals to the labeling control system. At the appropriate position, the control system controls the corresponding motor to send out the label and attach it to the position where the product is to be labeled. The product flows through the labeling device, and the labeling tape drives the product to rotate. The label is rolled over, and the labeling action of one label is completed;

Operation process: Product placement (can be connected to the assembly line) ->Product conveying (automatically implemented by equipment) ->Product spacing (automatically implemented by equipment) ->Labeling (automatically implemented by equipment) ->Labeling (automatically implemented by equipment) ->Collect labeled products."