Product Details

Model:

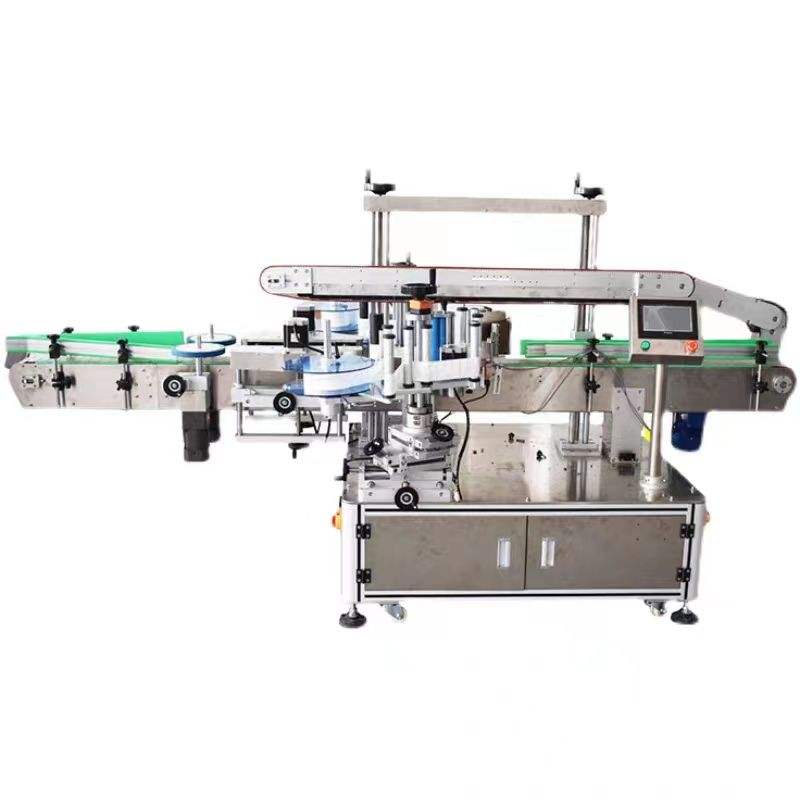

ET-FAL2S

Specifciation:

Size:L*W*H 2800*1500*1750mm

Applicable bottle diam:L:15~400mm W:20~90mm H:60~320mm

Applicable Label Size:L:20~350mm W:20~250mm Or customized

Power Supply:AC220V 50/60Hz

Max outer diameter of the label roll:380mm

Inner diam of the label roll:75mm

Labeling speed:20~80 PCS/min

Weight:350KG

Power:2200W

Labeling accuracy:±1mm

Product introduction:

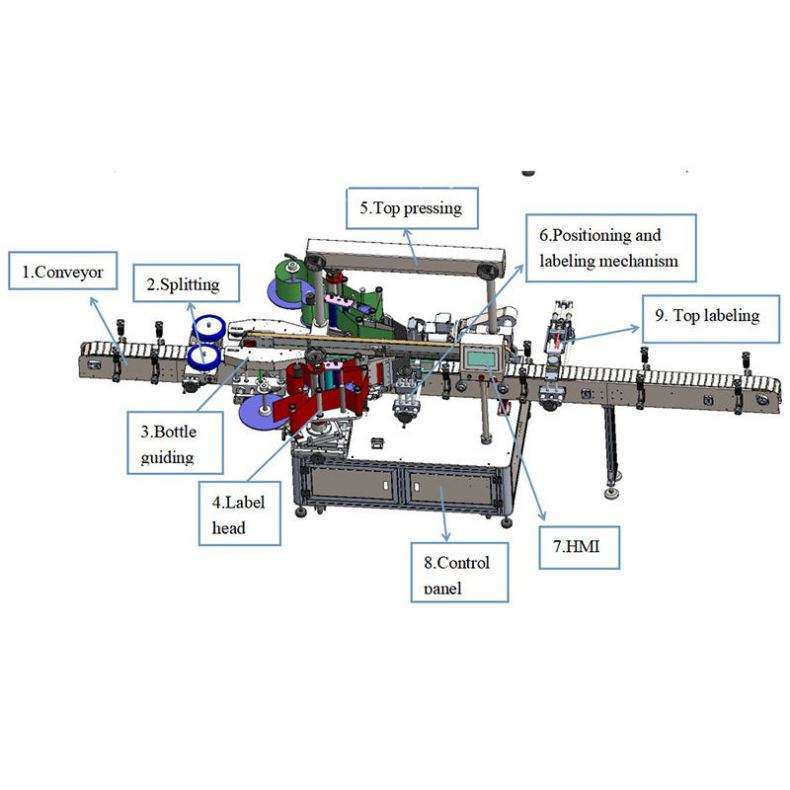

"The fully automatic double-sided labeling machine is a labeling machine that enables the simultaneous application of two labels on both sides of a product. Suitable for single-sided and double-sided labeling of flat bottles, round bottles, and square bottles, such as shampoo flat bottles, lubricant flat bottles, hand sanitizer round bottles, etc. Double sided labeling, with both sides affixed together, improves production efficiency, and is widely used in industries such as daily chemical, cosmetics, petrochemicals, and pharmaceuticals. Powerful function, one machine can achieve single-sided and double-sided labeling of 4 products (round bottle, flat bottle, square bottle, irregular bottle);

Related Suggestion

Online Consultation

———

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.