Product Details

Model:

"CD-ALFF2

CD-ALFF4

CD-ALFF6

CD-ALFF8

CD-ALFF10

CD-ALFF12"

Specifciation:

"Filling Nozzle:4、6、8、10、12(customzied)

Filling Scope: 100ml-1000ml,500ml-5L(customized)

Speed:150-180bottle/h/head

Filling Accuracy:<±0.3%

Power Supply:380V 60HZ /50HZ

Air Pressure:4-6MPa

Size(L*W*H):2000mm×1500mm×2200mm

Weight:800kg"

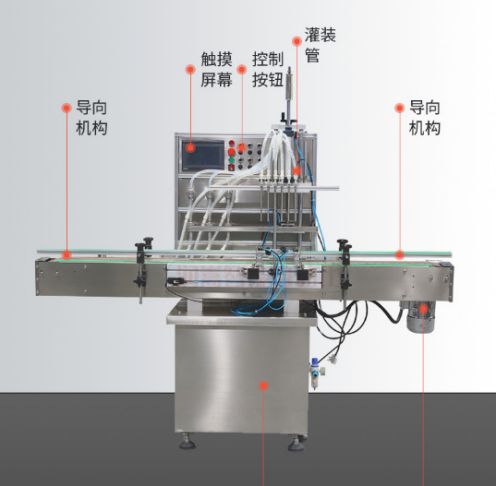

Product introduction:

"This machine adopts advanced computer programming controller (PLC), servo motor, servo driver, and imported sensors, making operation simple, fast, and accurate. Full color touch screen human-machine interface, the entire filling process can be automatically filled by setting the filling amount and number of filling heads through the touch screen on the equipment, and the process is basically one click operation. Multiple heads can be filled simultaneously, and the number of filling heads can be increased or decreased as needed. Easy to clean, easy to adjust, and the volume cylinder body has stepless speed regulation, suitable for filling different specifications and liquids. The filling amount is adjusted in one go, and each volumetric cylinder can be slightly adjusted separately, with high filling accuracy and good consistency. Imported deceleration servo motor with stepless speed control for filling piston cylinder, suitable not only for various water agents but also for viscous liquids. The imported electromagnetic clutch and electromagnetic brake work together to eliminate inertia and achieve high filling accuracy.

Product features:

Supported by PLC software, servo motors, servo drivers, and adjusters only need to set the target quantity on the touch screen, and the equipment can automatically increase or decrease to reach the target quantity. Color touch display operation, monitoring and other various functions.

Wide applicability and easy adjustment

Suitable for filling most bottle types (especially irregular bottles), easy to adjust the quantity

Adopting anti drip and wire drawing filling plugs, anti high foam product filling lifting system, positioning system to ensure bottle mouth positioning, and liquid level control system."

Related Suggestion

Online Consultation

———

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.