Product Details

Model:

"CD-ALWF2

CD-ALWF4

CD-ALWF6

CD-ALWF8

CD-ALWF10

CD-ALWF12"

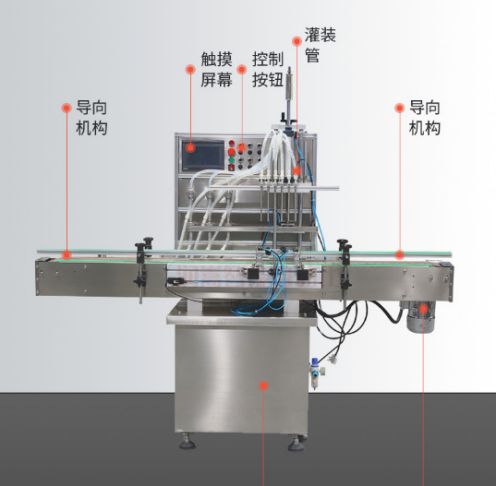

Product introduction:

"The weighing filling machine utilizes the high measurement accuracy of electronic scales by connecting electronic weight signal sensors with weighing control instruments through data cables. During the measurement process, the pressure signal of the electronic scale is continuously transmitted to the control instrument. When the preset quantitative weight is reached, the control instrument controls the pump to stop and closes the pneumatic valve. This weighing filling machine is connected to the tank body through pipes and adopts self pressure filling, and is weighed by the equipment's own weighing system. The pipeline connections are quick to install, making disassembly and cleaning convenient and fast. The parts in contact with the material and the leakage part are made of stainless steel material. The whole machine is safe, environmentally friendly, hygienic, and beautiful, and can adapt to various working environments. It can fill food, medicine, daily chemical edible oil, salad oil, butter, cream, paint, lubricating oil, engine oil, pesticides, liquid fertilizers, foliar fertilizers, flushing fertilizers, diluents and other materials.

Product features:

1. Equipped with automatic skinning function, automatic weight detection, and automatic submerged filling.

2. Set the required filling weight arbitrarily within the design scope.

3. The end of the filling process adopts a variable frequency deceleration system, which automatically decelerates when approaching the quantitative value to prevent overflow.

4. Adopting a vacuum suction anti drip filling nozzle to prevent material leakage.

5. Adopting double or triple row conveyor belts and push rod type bucket feeding greatly saves space on the site."

Specifciation:

Related Suggestion

Online Consultation

———

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.