Product Details

Model:

"CD-SALGF2

CD-SALGF4

CD-SALGF6"

Specifciation:

"Filling Nozzle:1、2、4(Customized)

Speed:80-150buckets/h/head

Filling Scope:1-10kg

Accuracy:≤0.5%

Power:4KW

Weight:180Kg

Size(L*W*H):1000X400X700MM"

Product introduction:

" The system adopts a weighing filling method with high measurement accuracy and is not affected by materials.

A feeding valve consisting of fast and slow additives can improve both filling speed and accuracy.

The measurement range is large, with a measurement error of less than 5 grams per barrel.

The filling head adopts a vacuum suction anti drip device, which produces no bubbles in the filled material and has a good effect.

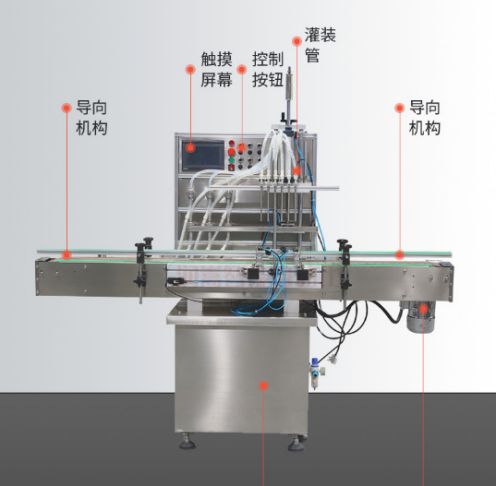

Main structure and working principle

The computerized quantitative filling machine consists of a feeding system, weighing system, rack, pneumatic control, control system, etc.

Feeding method: Continuous and stable feeding is required (using a feeding pump or hopper for pressurized feeding).

Filling methods: ordinary conventional filling and lifting submerged filling (to be selected when ordering according to needs)

The weighing system is supported and filled by weighing brackets, sensors, weighing platforms or unpowered rollers and racks.

The end of the filling process adopts a variable frequency deceleration system, which automatically decelerates when approaching the quantitative value to prevent overflow and ensure accuracy

Adopting a vacuum suction anti drip filling nozzle to prevent material leakage

The weighing platform is not allowed to be subjected to additional external forces during use."

Related Suggestion

Online Consultation

———

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.