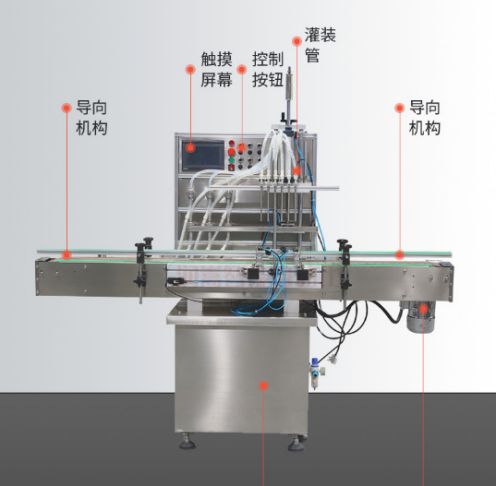

Product Details

Model:

CD-ALSJ1

Specifciation:

"Filling Nozzle:1

Filling Scope:200L/1000kg

Filling Scope:200L /1000kg

Speed(water):15-20drums/h(200L) 8-12drums/h(IBC)

Accuracy:±0.1%

Size(L*W*H) :2000*1600*2500mm

Weight: 800kg"

Product introduction:

"1、 Main features

Suitable for 200L/1000kg filling containers, achieving visual positioning, automatic opening and closing of barrel lids, and automatic completion of other filling barrel supply, positioning, filling, weighing and measurement operations. The equipment has functions such as safety protection, no gas pollution, no leakage (leakage, dripping), and clean and environmentally friendly sealed filling. The whole line has a high degree of automation, using a weighing and fixed weight measurement method, which is fast and accurate in measurement.

2、 Main functions:

The system adopts PLC programmable controller control, photoelectric switch positioning, and fully automatic operation;

Professional grade gun filling, overall process production, to prevent dripping and splashing; Quick connector, easy to disassemble and wash;

Quick start/emergency stop operation for gun filling, adjustable gun filling height, suitable for filling various packaging barrels;

■ Free selection of net weight/gross weight, automatic/manual filling method;

Automatic peeling, fault detection, real-time display of equipment information, stable efficiency;

Good filling stability, reduced losses, cost savings, improved operational efficiency, and product qualification rate.

3、 Operation process:

Manually place empty buckets in the empty bucket area and automatically transport them to the filling scale platform;

■ Automatic positioning of barrel mouth, automatic opening of machine lid, automatic insertion of filling head into barrel mouth to start filling;

After the filling is completed, the filling gun is automatically lifted outside the barrel, and the drip tray is automatically connected to the bottom of the filling gun or vacuum suction is used to complete the filling;

The machine automatically completes the capping process and transports it outside the filling area."

Related Suggestion

Online Consultation

———

First class quality service and professional after-sales team.

Factory address:Your company's full name

Office address:Your company's full name

Get in Touch

*We respect your confidentiality and all information are protected.

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.